Industrial growth often comes with an invisible price—toxic wastewater full of heavy metals like lead, chromium, cadmium, mercury, and arsenic. These metals pose a serious threat to water bodies, agriculture, and human health if not treated properly.

At Waterix.in, we believe clean water is not a luxury—it’s a responsibility. That’s why we focus on smart, efficient, and sustainable water treatment solutions, including Effluent Treatment Plants (ETPs) capable of removing even the most dangerous heavy metals.

This article explains how ETPs work, the best methods for heavy metal removal, and how 3D Aqua Solutions delivers top-tier industrial wastewater treatment systems tailored to your needs.

🏭 What is an Effluent Treatment Plant (ETP)?

An Effluent Treatment Plant is designed to purify industrial wastewater before releasing it back into the environment or reusing it within the facility. Unlike standard sewage systems, ETPs tackle complex pollutants, including dissolved metals, acids, oils, and organic chemicals.

Heavy metals are particularly dangerous because they are non-biodegradable and accumulate in the environment, causing long-term damage.

❗ Why Heavy Metal Removal is Crucial

- ⚠️ Non-degradable: Heavy metals remain in ecosystems forever unless removed

- 🧬 Toxicity: Can lead to cancer, organ damage, and neurological disorders

- 🌾 Agricultural Impact: Polluted water degrades soil and crops

- 🧾 Legal Compliance: CPCB and SPCB regulations require industries to treat effluents properly

- 🌎 Environmental Safety: Prevents contamination of rivers, lakes, and groundwater

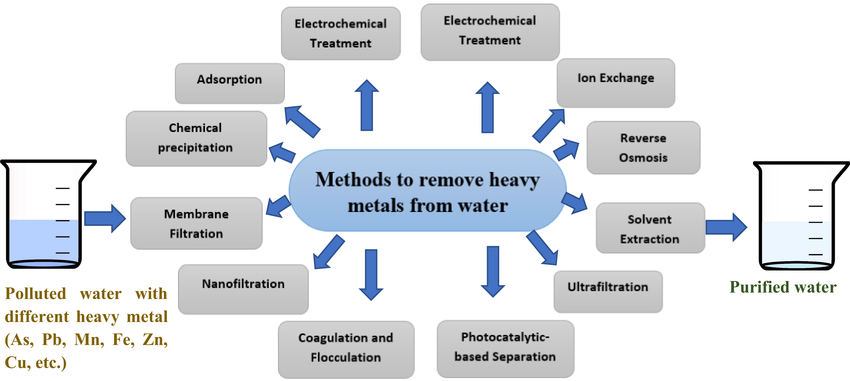

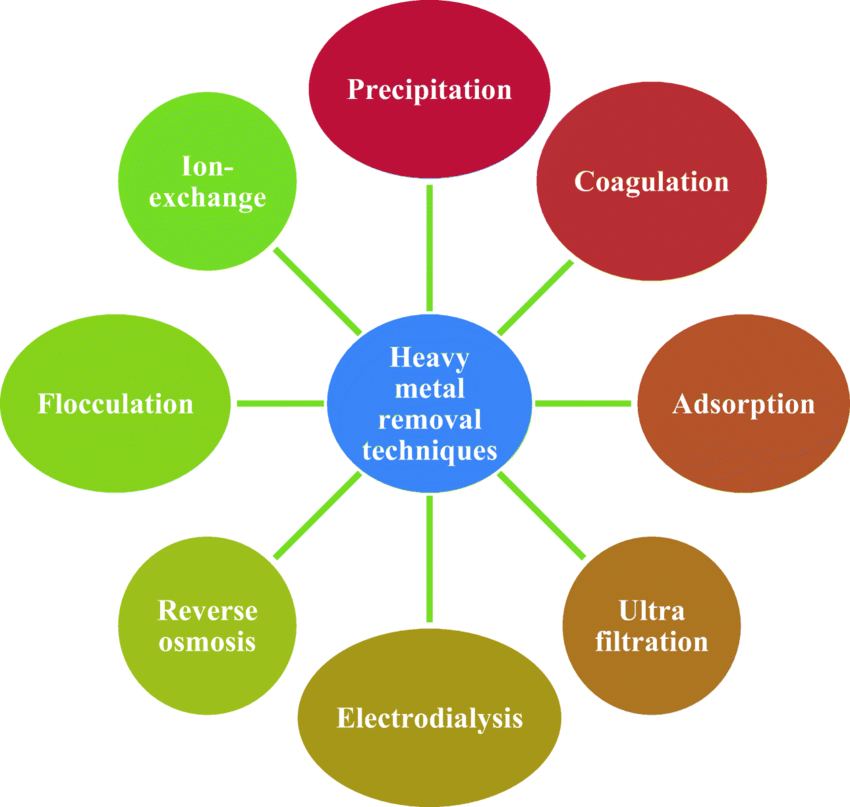

🔬 Top ETP Methods to Remove Heavy Metals

1️⃣ Chemical Precipitation

A cost-effective and widely used method. Metal ions react with chemicals (like lime or caustic soda) to form insoluble compounds, which are then filtered out as sludge.

- Ideal for: Zinc, Chromium, Lead

- Removes up to 95% of metal load

2️⃣ Coagulation & Flocculation

Used to clump fine particles and make them settle easily.

- Chemicals used: Alum, Ferric Chloride

- Prepares wastewater for further treatment steps

3️⃣ Ion Exchange

This process replaces heavy metal ions in wastewater with harmless ions using resin beads.

- Highly efficient for trace metal removal

- Used in: Pharmaceuticals, Electronics, Plating

4️⃣ Adsorption

Activated carbon or natural adsorbents trap metal ions from water.

- Low-cost polishing step

- Removes metals like arsenic, mercury

5️⃣ Membrane Filtration (UF, NF, RO)

Membranes offer high-precision removal of dissolved metals and salts.

- UF → removes suspended particles

- NF → targets divalent metals

- RO → removes 99% of all dissolved impurities

6️⃣ Electrochemical Treatment

Electrocoagulation and advanced oxidation use electricity to remove metals and break down complex compounds.

- Ideal for: Battery, Paint, and Chemical Industries

🔧 3D Aqua Solutions: Smart ETPs for Heavy Metal Removal

3D Aqua Solutions, a trusted name in the Indian water industry, designs custom ETPs for industries with complex wastewater challenges. Their systems are ideal for:

- ✅ Battery Recycling

- ✅ Metal Finishing & Electroplating

- ✅ Textile & Dyeing

- ✅ Pharmaceuticals

- ✅ Automobile Parts & Forging Units

Features of 3D Aqua ETP Systems:

- SCADA-based automation

- Energy-efficient design

- ZLD compliance

- Modular & compact layouts

- Real-time monitoring dashboards

Their goal is simple: efficient heavy metal removal with minimum footprint and operating cost.

📊 ETP Process Flow (For Heavy Metal-Laden Effluent)

nginxCopyEditIndustrial Effluent

↓

Screening & pH Correction

↓

Coagulation & Flocculation

↓

Heavy Metal Precipitation

↓

Clarification (Settling Tank)

↓

Sand & Carbon Filtration

↓

Ion Exchange or RO Membranes

↓

Safe Discharge or Water Reuse

✅ Benefits of Using ETPs from Waterix.in

| Benefit | Description |

|---|---|

| 🧼 Clean Discharge | Meets CPCB & SPCB standards |

| 🔁 Reuse of Water | Recycles up to 80% of wastewater |

| 💰 Cost Savings | Cuts water bills and environmental fines |

| 🧾 Compliance | Avoids shutdowns and legal issues |

| 🌍 Environmental Responsibility | Reduces pollution and improves ESG profile |

📈 Real Use Case

A chrome-plating unit in Ludhiana struggled with high hexavalent chromium levels. After installing a 3D Aqua ETP system through Waterix.in:

- Chromium reduced by 98%

- Sludge volume decreased by 60%

- Plant saved ₹50,000/month by recycling treated water

🌿 Conclusion

Industries cannot afford to overlook the dangers of heavy metal pollution. A well-designed ETP not only ensures regulatory compliance but also supports long-term sustainability and water reuse.

At Waterix.in, we bring you industry-specific, cost-effective ETP systems that remove even the most persistent pollutants. Partner with us and turn your wastewater into a resource—not a liability.

📞 Need a custom ETP for your business?

Visit www.waterix.in or contact us for a free consultation and site survey.

Home

Home  Whishlist

Whishlist  Contact

Contact  Checkout

Checkout